Getting It To Stay In Place

Modern Affixing

The First Solution: PMMA Bone Cement

Sir John Charnley, the father of modern joint replacement, pioneered the idea of using PMMA (polymethylmethacrylate) bone cement to attach the implant to the surrounding bone in the late 1950s. This method is still in wide use today.

An implant that is designed to be used with bone cement has a smooth surface, like the one shown here. The bone in which it will be placed is hollowed out to be wider than the implant and the cavity is filled with cement. The replacement joint is pushed into the cement, which then hardens to bond the replacement joint to the patient’s own bone.

An implant that is designed to be used with bone cement has a smooth surface, like the one shown here. The bone in which it will be placed is hollowed out to be wider than the implant and the cavity is filled with cement. The replacement joint is pushed into the cement, which then hardens to bond the replacement joint to the patient’s own bone.

The Latest Success: Porous Coating

Bone is alive and can grow and mend itself. For decades, researchers had experimented with the idea of encouraging bone to grow through or into implants, but the idea only became workable in the 1970s.

Bone is alive and can grow and mend itself. For decades, researchers had experimented with the idea of encouraging bone to grow through or into implants, but the idea only became workable in the 1970s.

Joints that are designed to be held in place by “biological fixation” are covered with a network of tiny metal balls. Rather than being smooth and shiny, these implants have a matte, textured surface.

The patient’s body responds as it would to a broken bone – the living bone grows to bridge the gap. By growing into the spaces between the metal balls, the fabric of the real bone and the replacement become interwoven.

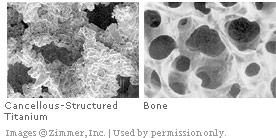

The design of porous coatings continues to evolve, with new metal structures, right, that more closely resemble the structure of real bone, far right.

The design of porous coatings continues to evolve, with new metal structures, right, that more closely resemble the structure of real bone, far right.

Porous-coated implants are chosen primarily for younger patients, whose bone grows at

a faster rate.

| Discover some of the odder ingredients used in the past! |